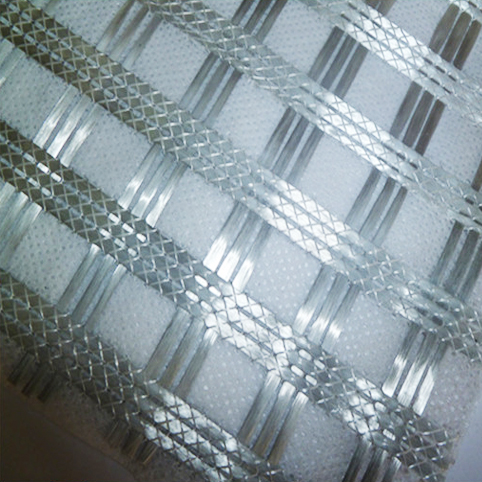

Fiberglass Geo Composite

Fiberglass Geo Composite are made from the highest quality fiberglass and are made into form a dimensionally stable fiber network. Whether used in roadways, railroads or landfills, our Fiberglass Geo Composite can add years to the life of your project.

Model : ZHBF

![]()

![]()

Feature:

Fiberglass Geocomposite is composed of Fiberglass and Polypropylene needle punched non-woven. It is one new geosynthetics material which is used in the construction and reconstruction of asphalt road surface to avoid reflective split, water damage and reinforcement road surface strength. After absorbing asphalt material, Fiberglass Geoomposite will shape into a stable construction layer possessing physical properties such as perfect waterproof performance, high heat resistance and good anti-corrosion ability and with many advantages as high tensile strength, low expansion coefficient, good tenacity and convenient in construction. Especially, it will increase the ability of anti-cracking at low temperature, high temperature track resistance, fatigue crack resistance, suspending reflective split to extend service life of road after compounding with asphalt material.

Performance:

(1)Preventing permeating performance. Fiberglass Geocomposite is composed of Fiberglass and Polypropylene needle punched non-woven. It can stand high temperature asphalt material. After composing with asphalt material, the Polypropylene needle punched non-woven will form a continuous and ametabolic waterproof layer to effectively prevent water permeating and avoid the damage of roadbed and surface cause by water permeating.

(2)The anti-crack performance Fiberglass Geocomposite is high tensile strength at low elongation. It can effectively eliminate the stress concentration in the junction or cracking place, reduce the expansion and upward radiation of the crack on the road surface, suspend the reflective split, extend service life of road largely reduce road maintenance costs.

(3)Temperature resistance performance Fiberglass Geocomposite reinforced by fiberglass. It possesses high heat resistance and perfect cold proof performance. The normal working temperature is -100 degree --- -280degree. So there is no regional restriction.

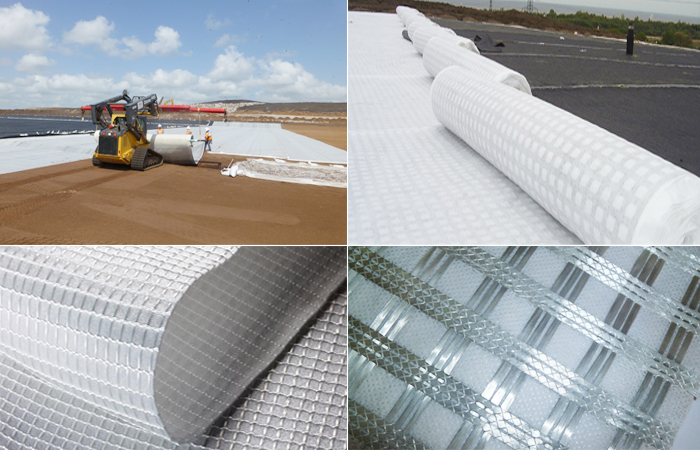

Engineering application:

(1)Road surface construction, reconstruction and widening.

(2)Paving asphalt pavement on the old cement concrete road.

(3)Repairing split of the asphalt road surface, or maintenance of old asphalt road.

| Item: ZHBF | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||